Why to use fuel additives

Fuel Quality, Octane & Cetane – How CarPills Fits In

Fuel producers must meet minimum quality standards set by law.

For example, diesel fuel sold in the UK and EU must meet a minimum cetane number of 51, while standard petrol must meet a minimum octane rating of 95.

These values ensure reliable engine operation. However, how efficiently fuel burns in real-world conditions can vary depending on fuel composition, engine type, and operating conditions.

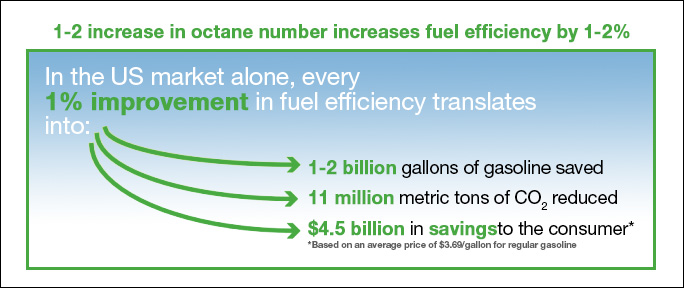

Increasing the cetane and octane performance can improve fuel efficiency, lower the emissions and therefore it can also lower your fuel expenses. You can see the example in the chart below:

Combustion Efficiency Matters More Than the Label

Octane and cetane numbers describe how fuel behaves during combustion, not how much energy it contains. Improving combustion quality beyond minimum standards can support:

- More stable and complete combustion

- Reduced fuel waste

- Lower emissions

- Improved overall efficiency

This is where CarPills is designed to help.

Independent Laboratory Testing

CarPills has been tested by an independent laboratory to evaluate its effect on diesel fuel combustion characteristics.

Under controlled test conditions, diesel fuel treated with CarPills showed a higher measured cetane number compared to an untreated sample. This demonstrates that CarPills can positively influence combustion behaviour under laboratory conditions.

Actual results may vary depending on fuel composition, dosage, engine design, and operating conditions.

CarPills is not marketed as a guaranteed cetane or octane booster, nor does it change the certified fuel rating declared by fuel suppliers.

What This Means in Practice

Rather than focusing on chasing fuel rating numbers, CarPills is designed to support cleaner and more efficient combustion of the fuel already being used.

In real-world use, this can deliver benefits similar to higher-quality fuel, without requiring drivers to change fuel type, modify their vehicle, or alter driving habits.

Additional Engine Protection Benefits

In addition to supporting improved combustion, CarPills helps protect the engine by:

- Reducing friction during combustion

- Supporting cleaner burning

- Helping keep the engine and fuel system cleaner over time

CarPills is intended as a complementary fuel additive and is not a replacement for regular vehicle maintenance or servicing.

Important Note

Results may vary depending on vehicle condition, fuel quality, mileage, and driving style.

Stabilizer and anti-oxidant

Distillate (diesel) fuels are organic in nature and begin to degrade from the point of manufacture (refining) until use. Car Pills additive is designed to help retard natural hydrocarbon degradation of diesel fuels and distillate fuel oils, particularly during extended storage periods.

Cleaner

Car Pills advanced additive is used to help clean carbon and gummy deposits from diesel fuel delivery and injection systems, helping maintain a proper diesel fuel spray pattern. Improved injector cleanliness supports more complete combustion and more consistent engine performance.

Lubricity

Modern Ultra Low Sulphur diesel fuels have reduced natural lubricity. Car Pills contains lubricity-enhancing components designed to help reduce friction in diesel fuel pumps and injectors, supporting smoother operation and reduced wear.

Graphene

Graphene is a single layer of carbon atoms arranged in a two-dimensional lattice, valued for its exceptional mechanical and friction-reducing properties. In fuel and lubrication-related applications, graphene has attracted attention for its potential to reduce friction and wear at the microscopic level.

Graphene as Nano Lubricant

Laboratory studies have shown that graphene layers can significantly reduce friction and wear on sliding metal surfaces under controlled conditions. In fuel additive formulations, graphene-based nanoparticles are used to support boundary lubrication, helping reduce friction during operation. Even partial surface coverage has been shown to be effective in laboratory testing due to graphene’s ability to reorient during initial wear cycles.

Benefits of graphene as a lubricant:

- Extremely low friction behaviour observed in laboratory testing

- Supports reduced friction and wear

- Effective across a wide range of operating environments

Power, fuel efficiency

Independent Engine Dyno Testing Without and With Diesel Fuel Additive:

Subsequent engine efficiency improvements have been well documented in large fleet use.

Independent engine dynamometer testing and field trials have shown improvements in engine efficiency when diesel fuel additives were used under specific operating conditions. Documented trials have reported fuel efficiency improvements in the range of approximately 3–5% for slow-to-medium speed diesel engines and up to 5–8% for high-speed diesel engines, depending on engine type, duty cycle, and operating conditions.

(Actual results may vary depending on engine condition, fuel quality, and operating environment.)

Test methods employed were:

- Specific fuel consumption.

- Exhaust Carbon Balance.

- Statistical Computer Model.

The Exhaust Carbon Balance method (AS2077-1982) offers the most accurate, quick and hassle-free test method. This is because it measures instantaneous flow rates. The above results have been confirmed in controlled trials at Curtin University’s thermo-dynamics laboratory (WA). Quite simply, less fuel is required to do the same work, and more power is produced for the same throttle setting. This is because it measures instantaneous flow rates. The above results have been confirmed in controlled trials at Curtin University’s thermo-dynamics laboratory (WA). Quite simply, less fuel is required to do the same work, and more power is produced for the same throttle setting.

Picrate

Picrate acts primarily as a combustion support additive. It does not alter fuel specifications or increase the intrinsic energy content of the fuel, helping to maintain compatibility with engines and preserve warranty considerations.

Its effect is largely physical: the solvent carrier assists fuel atomisation during injection, increasing the fuel surface area exposed to air. In this environment, picrate microcrystals can form, which can aid ignition and promote multiple flame fronts. This can lead to faster, more complete combustion under controlled conditions.

Picrate – Supporting Combustion and Efficiency

Picrate helps improve the oxidation of fuel components. By promoting more efficient combustion, ignition delay may be reduced, flame propagation can be more uniform, and peak cylinder pressures can be reached more consistently. In practice, this supports smoother engine operation and can help reduce the formation of incomplete combustion by-products.

Picrate – Observed Effects in Testing

Laboratory and field evaluations have indicated that picrate-containing fuel additives can support reductions in emissions of hydrocarbons (HC) and carbon monoxide (CO) under certain operating conditions. Actual results vary depending on fuel type, engine design, and operating parameters.

Picrate – Practical Benefits

In real-world use, picrate contributes to:

- Cleaner combustion and reduced soot formation

- Improved fuel system cleanliness

- Support for overall engine efficiency

These benefits help operators reduce maintenance requirements, limit downtime, and improve operational efficiency when used alongside regular maintenance practices.

Cleaner oil

Cleaner combustion and cleaner oil go hand-in-hand. High carbon solids (soot) in lube oil is a very common complaint these days, which rapidly overloads the oil’s detergency/dispersancy package. Higher quality oils and more frequent change intervals might appear to be the correct action to take, but is, in fact, a ‘band-aid’ solution to a combustion problem. Picrate is of benefit by directly assisting combustion.

Biological growths

Components within the formulation may help limit conditions that encourage microbial growth in fuel systems, supporting cleaner fuel storage and handling.

Some results from tests

Long-term fleet trials reported reduced hard carbon deposits, improved engine cleanliness, and maintained compression in high-hour engines when treated fuel was used. Detailed findings from these trials are available on request.